We expect that this versatile tool will expand the throughput of biological experiments that require serial delivery of multiple fluids, from neuronal imaging in living organisms to histochemical staining of cells.

Afterwards, all subsequent experimental activity required no user intervention. organisms or cells), then selecting the chemical exposure time course and data acquisition settings.

In each example, the experiment was first set up by preparing a multiwell plate with desired chemicals, preparing the microfluidic device with bioassay targets (e.g. We demonstrate that this system, based on inexpensive open-source hardware and software, can completely automate: (1) the measurement of neural dose responses and optimization of chemical concentrations for robust and non-saturating responses, (2) a complex chemical screen to determine the effect of different solvents on optogenetically-activated neural responses in living nematodes, and (3) a multi-step, multi-duration cell staining protocol. In this manner, numerous liquids can be delivered sequentially into any microfluidic device. In this paper, we present a robotic system that reliably and automatically transfers a single microfluidic inlet tube from one fluid reservoir to another, without introducing a bubble. Rotational valves can change inlet streams without introducing bubbles, but are generally limited to 8 or 12 positions, while in-line debubblers can remove air from tubing, but occupy relatively large fluidic volumes, and both can be expensive and difficult to clean. However, any disconnection of tubing tends to introduce air bubbles due to surface tension, and these bubbles can severely disrupt fluid flow within microfluidic circuits.

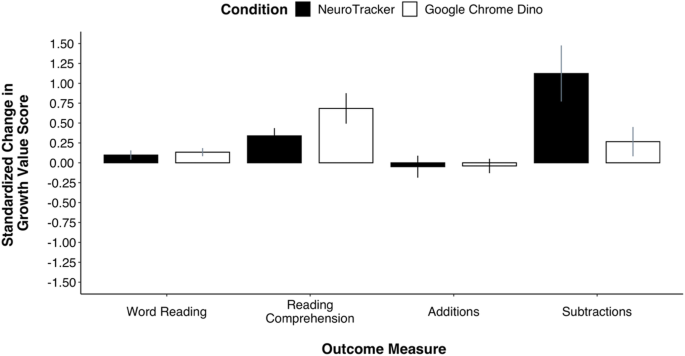

#Neurotracker comparisons manual

A simple yet laborious alternative is the manual transfer of an inlet tube from well to well 17. These approaches are generally expensive, either due to laborious fabrication processes or to single-use cartridges operated by specialized flow control equipment. Current approaches include complex setups with separate inlet tubes for each well (i.e., 96 inlet tubes for a 96-well plate) 5, the use of conventional liquid-handling robots to inject liquids to device inlets 10, 11, and microfluidic designs that are integrated into plastic multiwell dishes 12, 13, 14, 15, 16. For dynamic chemical delivery and monitoring, such as stimulation with brief pulses of bioactive compounds, few options exist to directly interface chemicals in multiwell plates with microfluidic devices. Traditional high-throughput screening systems use multiwell plates to contain samples and chemicals in miniaturized wells and observe each condition after static long-term exposure periods, typically hours to days. Microfluidic devices offer several advantages for biomedical research, particularly for presenting precise physical and chemical environments to cells and organisms 1, 2, 3, 4, multiplexing experimental conditions 4, 5, 6, and reducing reagent volumes for screening applications 7, 8, 9. Together, these examples show that our system can automate various protocols and accelerate experiments by economically bridging two common elements of high-throughput systems: multiwell plates and microfluidics. Lastly, we automated an 85-minute, ten-step cell staining protocol. We then identified chemicals that suppressed optogenetically-evoked neural activity, demonstrating a functional screening platform for neural modulation in whole organisms. Next, we measured odor dose-response curves of in vivo neural activity from two sensory neuron types in dozens of living C. We first characterized reliability and performance by automatically delivering 96 dye solutions to a microfluidic device. Whereas current approaches to integrate microfluidic devices with multiwell plates remain expensive or technically complicated, we present here a simple open-source robotic system that delivers liquids sequentially through a single connected inlet. Interfacing these platforms in a simple and automated way would introduce new high-throughput experimental capabilities, such as compound screens with precise exposure timing. Multiwell plates are convenient for screening chemical libraries in static fluid environments, whereas microfluidic devices offer immense flexibility in flow control and dynamics. High-throughput biological and chemical experiments typically use either multiwell plates or microfluidic devices to analyze numerous independent samples in a compact format.

0 kommentar(er)

0 kommentar(er)